In the fast-paced world of food service and production, ensuring the food safety and quality of products is paramount. One crucial aspect often overlooked is the implementation of efficient food labeling systems. Dill Print emerges as a game-changer, offering a specialist solution that automates day dot printing, replacing the manual process and significantly enhancing food safety protocols.

The Significance of Day Dots:

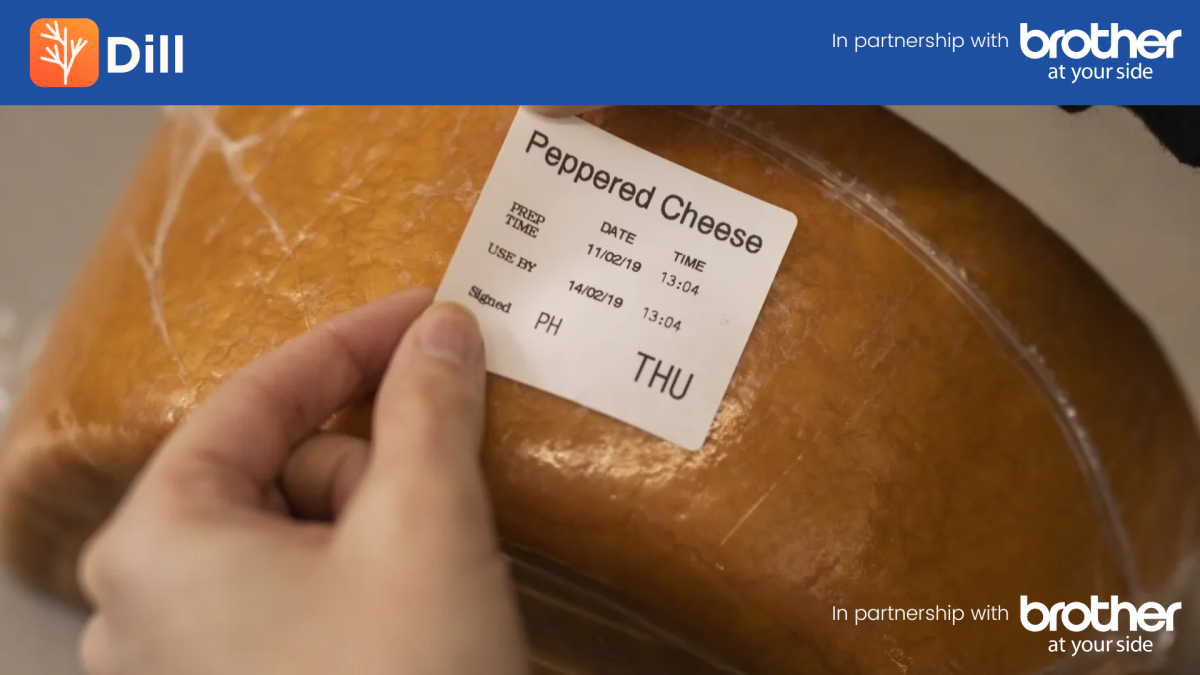

Day dots, also known as stock rotation labels, play a pivotal role in the food industry. These small labels carry essential information such as thawed, frozen, due dates, and more. The accuracy of these labels is critical in preventing foodborne illnesses, ensuring compliance with regulations, and maintaining the reputation of food establishments.

The Drawbacks of Manual Day Dotting in Stock Rotation:

In the past, day dots were handwritten, a method fraught with human error and time constraints. The manual process of jotting down labels not only heightened the risk of misinterpretation, potentially resulting in inaccurate information and hazardous outcomes, but it also demanded considerable labor hours. This diversion of resources could otherwise have been allocated to vital tasks in a bustling kitchen or food production facility.

Dill Print’s Automated Food Safety Solution:

Dill Print addresses these challenges head-on with its specialized food labeling solution. By automating day dot printing, Dill Print ensures accuracy, consistency, and efficiency in labeling. This not only reduces the risk of errors but also streamlines operations, allowing teams to focus on core responsibilities.

Automated Best Before Dates For Food Safety:

Dill Print’s automated system goes beyond basic day dotting. Best before dates are generated automatically, reflecting the correct due date based on the product name and category. This feature eliminates the need for manual calculation, reducing the burden on kitchen staff and minimizing the likelihood of mistakes.

Centralized Software for Seamless Food Safety Operations:

Dill Print introduces a centralized database for recipes and labels, revolutionizing the way food establishments manage their labeling processes. Instant updates to product ingredients are reflected in real-time across all recipes and labels, ensuring consistency and accuracy. This centralized approach simplifies the management of multiple sites, allowing for efficient updates and changes.

Flexibility Tailored to Your Needs:

Dill Print understands the diverse needs of the food industry. The solution offers flexibility in label customization, allowing for the addition of fields such as batch numbers, country of origin, cooking/storing instructions, barcodes, and more. Your branding is emphasized through custom logos and QR codes, serving marketing purposes while ensuring traceability.

Seamless Hardware Integration:

Dill Print’s partnership with Brother, a leading provider of thermal printing hardware, ensures a seamless and reliable printing experience. The integration with Brother thermal printers enhances connectivity through wireless printing, catering to large volumes and diverse operating systems, including Android, iOS, Mac, and Windows.

Conclusion:

In conclusion, the importance of automated day dot printing cannot be overstated in the food industry. Dill Print emerges as a specialist solution, transforming food safety protocols through accuracy, efficiency, and flexibility. By automating day dotting and streamlining labeling processes, Dill Print empowers food establishments to prioritize safety, compliance, and operational excellence. Embrace the future of food labeling with Dill Print and elevate your commitment to quality and safety.